Mini Pressure Gauges |

|

|

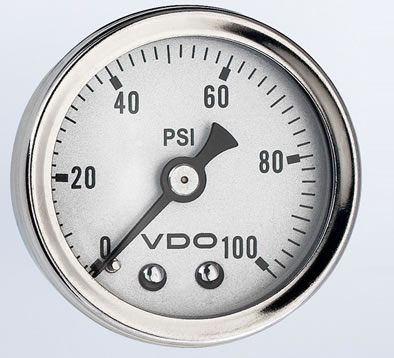

VDO Direct Mount 15PSI Mechanical Pressure Gauge

VDO Pressure Gauge

153-002 - VDO Direct Mount 15PSI Mechanical Pressure Gauge - Mini Pressure Gauges - Automotive Gauges - VDO

- Scale: 0 - 15 PSI

- Type: Mechanical

- Direct Mount

- Thread Connection: 1⁄8"-27NPT

- Diameter: 1 1⁄2" (38mm)

- Dial: White

- Bezel: Chrome

Precision machined brass movements, built in restrictors and polished stainless steel housings. Compatible with all fuel management systems.

|

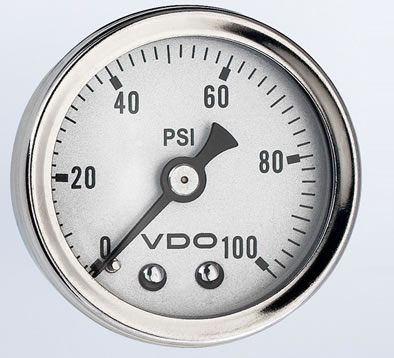

153-003 - VDO Direct Mount 100PSI Mechanical Pressure Gauge

|

|

|

VDO Pressure Gauge

Part-number:

VDO 153-003

- Scale: 0 -100 PSI

- Type: Mechanical

- Mounting: Direct

- Diameter: 1 1/2" (38mm)

- Dial: White

- Bezel: Chrome

1 1/2" direct mount pressure gauges feature precision machined brass movements, built in restrictors and polished stainless steel housings.

Compatible with all fuel management systems.

|

153-005 - VDO Direct Mount 60PSI Mechanical Pressure Gauge - Mini Pressure Gauges - Automotive Gauges - VDO |

|

|

VDO Pressure Gauge

Part-number:

VDO 153-005

- Scale: 0 - 60 PSI

- Type: Mechanical

- Direct Mount

- Thread Connection: 1/8"-27NPT

- Diameter: 1 1⁄2" (38mm)

- Dial: White

- Bezel: Chrome

|

153-112 - VDO Direct Mount 100PSI Mechanical Pressure Gauge |

|

|

153-112 - VDO Direct Mount 100PSI Mechanical Pressure Gauge - Mini Pressure Gauges - Automotive Gauges - VDO

VDO Direct Mount 100 PSI Mechanical Pressure Gauge, 1 1/2" (38mm) Diameter, Silver Dial

1 1/2" direct mount pressure gauges feature standard 1/8"-27NPT thread connection, precision machined brass movements, built in restrictors and polished stainless steel housings. Compatible with all fuel management systems.

|

SingleViu Pressure Gauges |

| |

VDO SingleViu Engine Oil Pressure Gauges 5Bar |

|

|

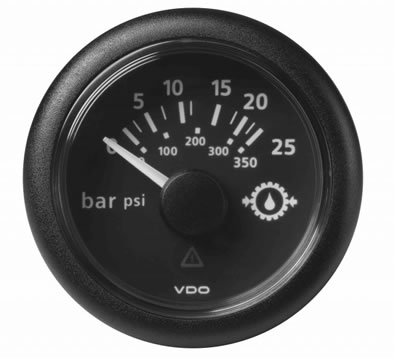

VDO SingleViu Engine Oil Pressure Gauge 5Bar Black 52mm

VDO SingleViu Engine Oil Pressure 5Bar Gauge

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 5 Bar - ISO 0248

Analogue signal: 10 - 184 Ohm

CANBus input: 65263 - 100 - 0x22

Connection cable order separately |

VDO SingleViu Engine Oil Pressure Gauges 10Bar |

|

|

VDO SingleViu Engine Oil Pressure 10Bar Gauge

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 10 Bar - ISO 0248

Analogue signal: 10 - 184 Ohm

CANBus input: 65263 - 100 - 0x22

Connection cable order separately |

VDO SingleViu Brake Pressure Gauges 16Bar |

|

|

VDO SingleViu Brake Pressure Gauge 16Bar Black 52mm

VDO SingleViu Brake Pressure 16Bar Gauge

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 16 Bar - ISO 1402

Analogue signal: 0.5 - 4.5 Volt

CANBus input: 65274 - 117 - 0x25

Connection cable order separately |

VDO SingleViu Gear Oil Pressure Gauges 25Bar |

|

|

VDO SingleViu Gear Oil Pressure Gauge 25Bar Black 52mm

VDO SingleViu Gear Oil Pressure Gauge 25Bar

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 25 Bar - ISO 1167

Analogue signal: 10 - 184 Ohm

CANBus input: 65272 - 127 - 0x23

Connection cable order separately |

VDO SingleViu Gear Oil Pressure Gauges 30Bar |

|

|

VDO SingleViu Gear Oil Pressure Gauge 30Bar Black 52mm

VDO SingleViu Gear Oil Pressure Gauge 30Bar

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 25 Bar - ISO 1167

Analogue signal: 10 - 184 Ohm

CANBus input: 65272 - 127 - 0x23

Connection cable order separately |

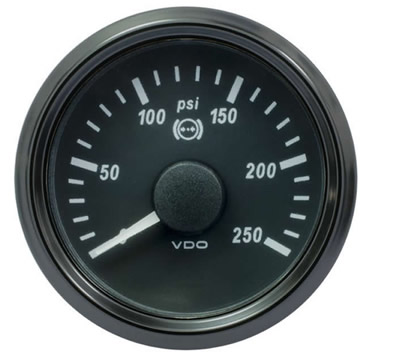

VDO SingleViu Air Pressure Gauges 150PSI |

|

|

VDO SingleViu Air Pressure Gauge 150PSI Black 52mm

VDO SingleViu Air Pressure Gauge 150PSI

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 150 PSI - Air

Analogue signal: 10 - 184 Ohm

CANBus input: Not available

Connection cable order separately |

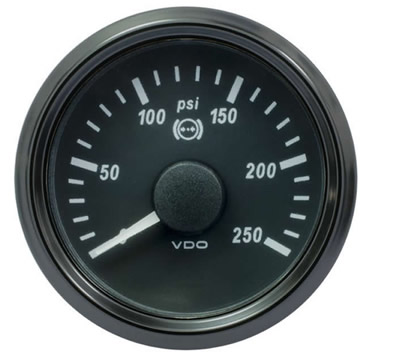

VDO SingleViu Brake Pressure Gauges 250PSI |

|

|

VDO SingleViu Brake Pressure Gauge 250PSI Black 52mm

VDO SingleViu Brake Pressure Gauge 250PSI

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 250 PSI - ISO 1402

Analogue signal: 0.5 - 4.5 Volt

CANBus input: 65274 - 117 - 0x25

Connection cable order separately |

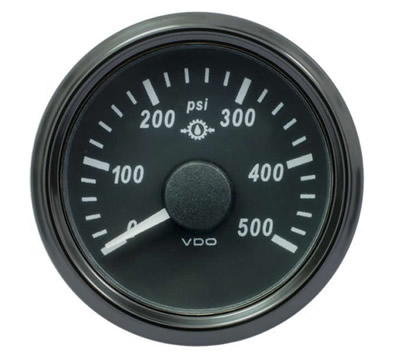

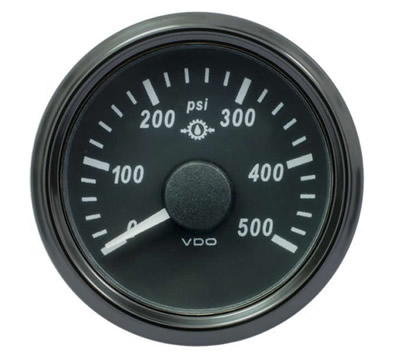

VDO SingleViu Gear Oil Pressure Gauges 500PSI |

|

|

VDO SingleViu Gear Oil Pressure Gauge 500PSI Black 52mm

VDO SingleViu Gear Oil Pressure Gauge 500PSI

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 400 PSI - ISO 1167

Analogue signal: 10 - 184 Ohm

CANBus input: 65272 - 127 - 0x23

Connection cable order separately |

VDO SingleViu Turbo Pressure Gauges 2Bar |

|

|

VDO SingleViu Turbo Pressure Gauge 2Bar Black 52mm

VDO SingleViu Turbo Pressure 2Bar Gauge

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 2 Bar - ISO 2107

Analogue signal: 10 - 184 Ohm

CANBus input: 65270 - 102 - 0x24

Connection cable order separately |

VDO SingleViu Turbo Pressure Gauges 60PSI |

|

|

VDO SingleViu Turbo Pressure Gauge 60PSI Black 52mm

VDO SingleViu Turbo Pressure Gauge 60PSI

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 60 PSI - ISO 2107

Analogue signal: 10 - 184 Ohm

CANBus input: 65270 - 102 - 0x24

Connection cable order separately |

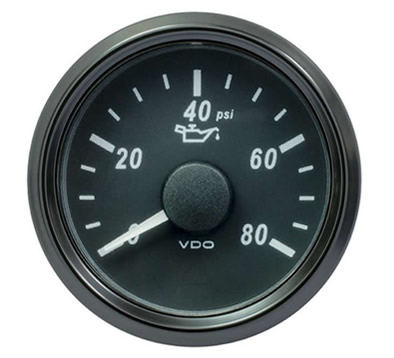

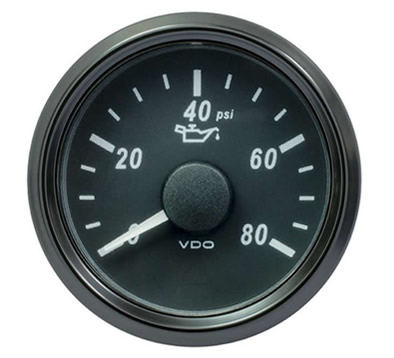

VDO SingleViu Engine Oil Pressure Gauges 80PSI |

|

|

VDO SingleViu Engine Oil Pressure Gauge 80PSI Black 52mm

VDO SingleViu Engine Oil Pressure Gauge 80PSI

Black - Hole: 52 mm - 2 1/16"

Operating voltage: 8-32 Volt DC

Range: 0 - 80 PSI - ISO 0248

Analogue signal: 10 - 184 Ohm

CANBus input: 65263 - 100 - 0x22 Connection cable order separately |

VDO VISION PRESSURE GAUGES |

| |

Vision Engine oil pressure gauges 10Bar |

|

|

VDO Vision Engine oil pressure 10Bar 52mm 12V

VDO Cockpit Vision Instruments are suited to runabouts and small cruisers.

Bezel and dial are matt black finish with white markings and red pointer.

Bezel diameter 52mm (2"). Lighting incorporated in all gauges excluding the hourmeter.

Features

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 10 Bar

- Operating voltage: 12 Volt DC

- Pressure gauge 10 to 184 Ohm - 500kpa

|

Vision Engine oil pressure gauges 5Bar |

|

|

VDO Vision Engine oil pressure gauge 5Bar 52mm 12V

Part-number:

VDO 350-010-008K

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 5 Bar

- Operating voltage: 12 Volt DC

- Retail package 1 Pressue gauge

- Clamp ring

Logistical information:

- HS Code: 85122000

- Ean Code: 4103590300676

- Weight: 0.20kg

|

Vision Pressure gauges 0 tot 3Bar |

|

|

VDO Vision Pressure gauge 0 tot 3Bar 52mm

Part-number:

VDO 150-015-001K

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 3 Bar Mechanical

- Aansluiting: M12 x 1.5

- Retail package 1 Pressue gauge

Logistical information:

- HS Code: 85122000

- Ean Code: 4103590300706

- Weight: 0.24kg

|

Marine Pressure gauges |

| |

|

|

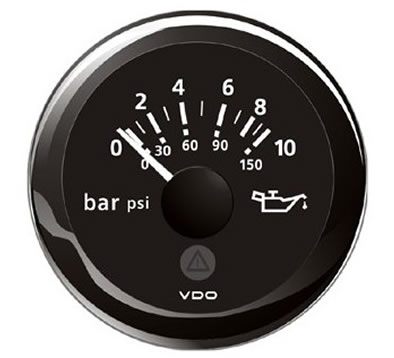

Black Engine Oil Pressure 5Bar |

|

|

Black Engine Oil Pressure 5Bar-80PSI - 12-24V DLRB

Part-number:

Veratron A2C59514123

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 5 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178722972

- Weight: 0.45kg

|

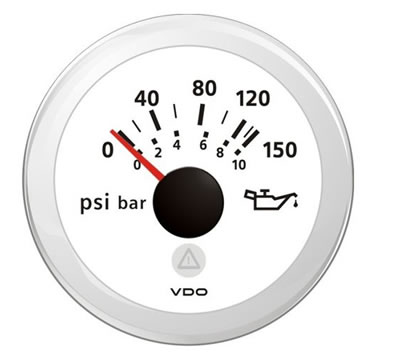

White Engine Oil Pressure gauges 10Bar |

|

|

White Engine Oil Pressure 10Bar-150PSI - 12-24V DLRW

Part-number:

Veratron A2C59514199

- Colour: White

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 10 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723160

- Weight: 0.45kg

|

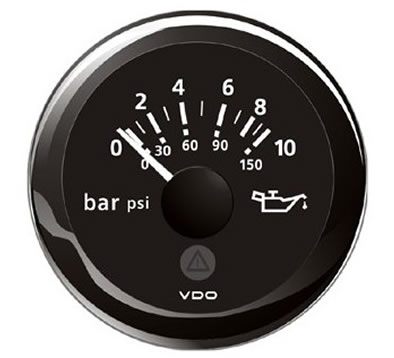

Engine Oil Pressure gauges 10Bar |

|

|

ViewLine Engine Oil Pressure 10Bar Black 52mm

Part-number:

Veratron A2C59514111

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 10 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178722965

- Weight: 0.45kg

|

Engine Oil Pressure gauges 150PSI |

|

|

Engine Oil Pressure 150PSI Black 52mm

Part-number:

Veratron A2C59514118

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 150 PSI

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178727472

- Weight: 0.45kg

|

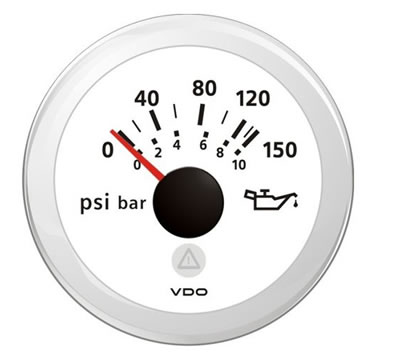

White Engine Oil Pressure gauges 150PSI |

|

|

Engine Oil Pressure 150PSI White 52mm

Part-number:

Veratron A2C59514202

- Colour: White

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 150 PSI

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723177

- Weight: 0.45kg

|

Marine Engine Oil Pressure gauges 25Bar |

|

|

Engine Oil Pressure 25Bar White 52mm

Part-number:

Veratron A2C59514206

- Colour: White

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 25 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723184

- Weight: 0.45kg

|

Marine Engine Oil Pressure 30Bar |

|

|

Engine Oil Pressure 30Bar White 52mm

Part-number:

Veratron A2C59514208

- Colour: White

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 30 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723191

- Weight: 0.45kg

|

Engine Oil Pressure gauges 5Bar |

|

|

Engine Oil Pressure 5Bar White 52mm

Part-number:

Veratron A2C59514211

- Colour: White

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 5 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723207

- Weight: 0.45kg

|

Marine Engine Oil Pressure Gauges 80PSI |

|

|

Engine Oil Pressure 80PSI Black 52mm

Part-number:

Veratron A2C59514128

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 80 PSI

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178722989

- Weight: 0.45kg

|

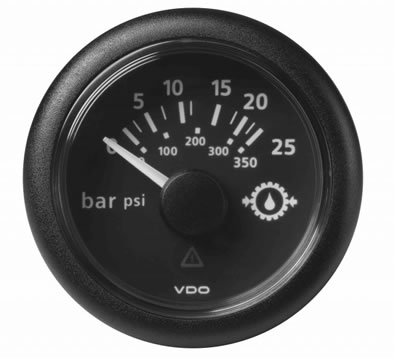

Gear Oil Pressure gauges 25Bar |

|

|

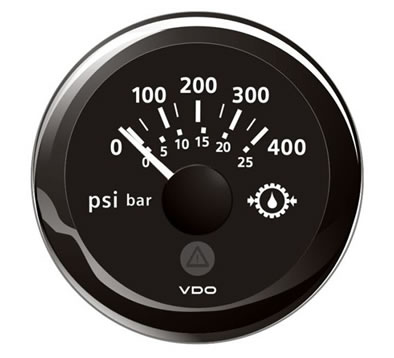

Gear Oil Pressure 25Bar-350PSI Black 52mm

Part-number:

Veratron A2C59514136

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 25 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178722996

- Weight: 0.45kg

|

Gear Oil Pressure Gauges 30Bar |

|

|

Gear Oil Pressure 30Bar Black 52mm

Part-number:

Veratron A2C59514141

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 30 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723009

- Weight: 0.45kg

|

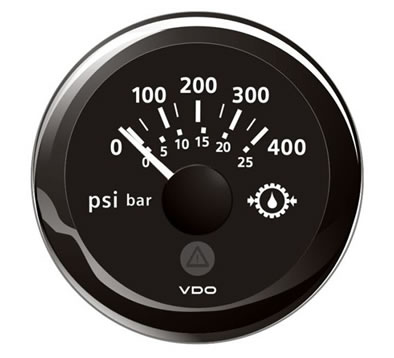

Gear Oil Pressure Gauges 400PSI |

|

|

Gear Oil Pressure 400PSI Black 52mm

Part-number:

Veratron A2C59514145

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 400 PSI

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723016

- Weight: 0.45kg

|

Marine Gear Oil Pressure Gauges 400PSI |

|

|

Gear Oil Pressure 400PSI White 52mm

Part-number:

Veratron A2C59514223

- Colour: White

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 400 PSI

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723214

- Weight: 0.45kg

|

Turbo Pressure Gauges 2Bar |

|

|

Turbo Pressure 2Bar Black 52mm

Part-number:

Veratron A2C59514149

- Colour: Black

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 2 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723023

- Weight: 0.45kg

|

Turbo Pressure Gauges 2Bar White |

|

|

Turbo Pressure 2Bar Gauges White 52mm

Part-number:

Veratron A2C59514225

- Colour: White

- Panel hole diameter: 52 mm - 2 1/16"

- Range: 0 to 2 Bar

- Lens: Dual - Anti-Fog

- Retail package 1 Pressure gauge

Logistical information:

- HS Code: 90262000

- Ean Code: 7640178723221

- Weight: 0.45kg

|

Industrial Pressure Gauges |

| |

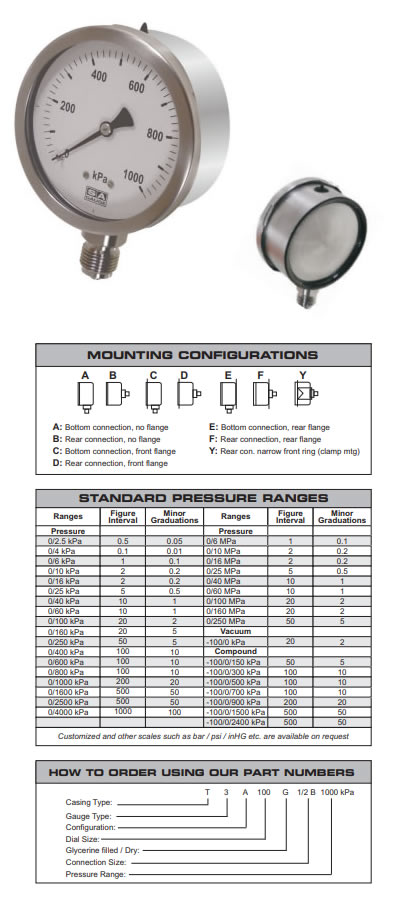

General Purpose Industrial Pressure Gauges |

|

|

General Purpose Industrial Pressure Gauge

Suitable for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be in the hydraulic, pneumatic, refrigeration, steam, chemical and food and beverage industry

- Case Details - Nominal Dia: 40, 50, 63, 80, 100, 160mm

Material: Stainless steel 304

- Bezel - S/Steel rolled ring type - tamper proof.

Material: Stainless steel 304

- Mounting Flange - Material: Polished stainless steel 304

- Pressure Element - Material: Type 3: Cu-alloy Type 4: Stainless steel 316

- Geared Movement - Material: Clockwork brass or stainless steel.

- Pointer - Collet: Aluminium or brass Blade: Black aluminium

|

Process Industrial Pressure Gauges |

|

|

Process Industry Gauges

Suitable for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be in the hydraulic, pneumatic, refrigeration, steam, chemical and food and beverage industry.

- Case Details - Nominal Dia: 63, 100, 160, 250mm

Material: Stainless steel 304

- Bezel - Bayonet lock, twist type - removable.

Material: Stainless steel 304

- Mounting Flange - Material: Polished stainless steel 304

Position: See “Mounting Configurations”

- Operating Temperature

Ambient: -20 °C to + 60 °C

Medium: +70 °C ( soldered tube ): + 100 °C ( brazed / tig

wellded tube ) For live steam use, a syphon tube is recommended.

|

Capsule Low Pressure Industrial Gauges |

|

|

Capsule Low Pressure Industrial Gauge

Suitable for measuring low pressure / vacuum in gaseous, non-aggressive dry media that does not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be in the medical, laboratory, vacuum and filter monitoring industry.

- Case Details - Nominal Dia: 63, 80, 100, 160mm

Material: Stainless steel 304

- Bezel - Sizes 63, 80 & 100mm Roll ring type - tamper proof.

Size 160mm Bayonet locking, twist type - removable.

Material: Stainless steel 304

- Pressure Ranges - 0 to 2.5...40 kPa pressure or vacuum

- Working Pressure - Steady: Full scale value

Fluctuating: 90% of full scale value

|

Refrigeration Pressure Industrial Gauges |

|

|

Refrigeration Pressure Industrial Gauges

Suitable for refrigeration media such as freon and ammonia. Typical applications will be in the refrigeration and airconditioning industry.

- Case Details - Nominal Dia: 63, 80, 100 & 160mm diameter.

Material: Stainless steel 304

- Bezel - Standard - Type R: S/Steel rolled ring type - tamper proof.

Optional - Type T: S/Steel bayonet lock, twist type - removable.

Material: Stainless steel 304

- Pressure Connections - Material: Type 3: Brass. Type 4: Stainless steel 316 Sizes: 63 & 80mm dia: 1/8” & 1/4” in BSP or NPT or 1/4" flare. Sizes: 100 & 160mm dia: 1/4”, 3/8” & 1/2” in BSP or NPT or 1/4" flare

- Mounting Flange - Material: Polished stainless steel 304

Position: See “Mounting Configurations”

|

Diaphragm Operated Industrial Pressure Gauges |

|

|

Diaphragm Operated Pressure Industrial Gauge

Suitable for aggressive gaseous and liquid media under extreme conditions. Ddiaphragm gauges are suitable for viscous, crystallising or polluting media. The design ensures resistance to vibration and protection against over pressures.

- Case Details - Nominal Dia: 100 & 160mm

Material: Stainless steel 304.

- Bezel - Type T: S/Steel bayonet lock, twist type - removable.

Material: Stainless steel 304

- Pressure Connections - Material: Stainless steel 316.

Sizes : ½” BSP or NPT male or female threaded.

: Open flange on request.

Position: Radial bottom connection only.

- Measuring System - Diaphragm with push rod principle.

Material: Stainless steel 316.

|

Test Industrial Pressure Gauges |

|

|

Test Pressure Industrial Gauge

For pressure gauge testing and calibration laboratories. Suitable for media such as air, water, oil & gases that do not attack copper alloy parts.

- Case Details - Nominal Dia: 160 mm

Material: Stainless steel 304

- Bezel - Bayonet lock, twist type - removable.

Material: Stainless steel 304

- Pressure Connections - Material: Brass or Stainless steel 316

Sizes: 1/4”, 3/8” & ½” in BSP or NPT.

Position: See “Mounting Configurations”

- Geared Movement Material: Clockwork brass, wearing part argentan and bearings.

|

Tyre Industrial Pressure Gauges |

|

|

Tyre Pressure Industrial Gauge

Suitable for inspection of tyre air pressure in the automotive and industrial environment

- Case Details - Nominal Dia: 63 mm standard.

50, 80 & 100 mm dia on request.

Material: Stainless steel 304

- Bezel - Type R: S/Steel rolled ring type - tamper proof.

- Pressure Connections - Material: Type 3: Brass self sealing valve fitting.

Position: See “Mounting Configurations”.

- Pressure Element - Material: Type 3: Cu-alloy.

|

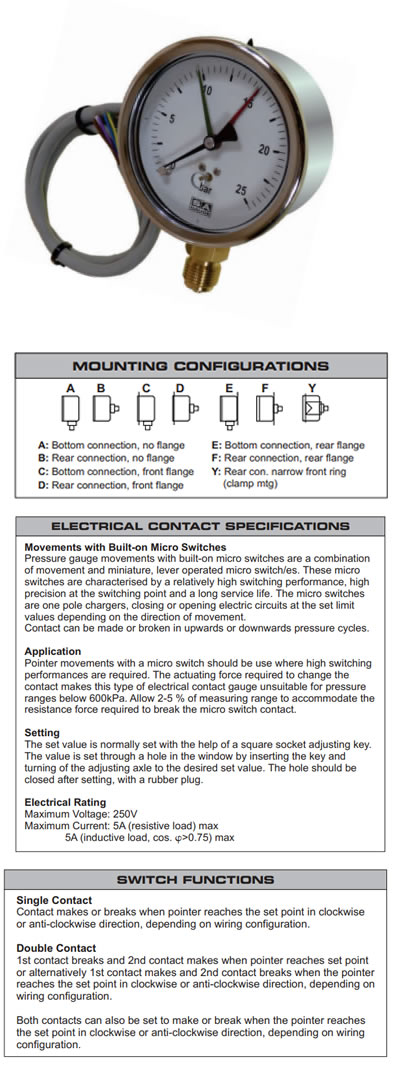

Electrical Contact Pressure Industrial Gauges |

|

|

Electrical Contact Pressure Industrial Gauge

ELECTRICAL CONTACT PRESSURE GAUGES: With external dome mounted snap action magnetic contacts are intended for the control and regulation of industrial processes where switching of electrical circuits are required for the industrial, mining and process industry.

Suitable for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be for the control and regulation of industrial processes where switching of electrical circuits are required. Externally adjustable, single or double contacts, can be fitted to a SA Gauge pressure gauge to make the gauge suitable to activate or deactivate electrical devices. Contact can make or break in an upward or downward pressure cycle.

- Financial Responsibility to Our Clients

- Superior Quality and Craftsmanship

- Quality and Value to the Projects We Deliver

- Highest Standards in Cost Control

|

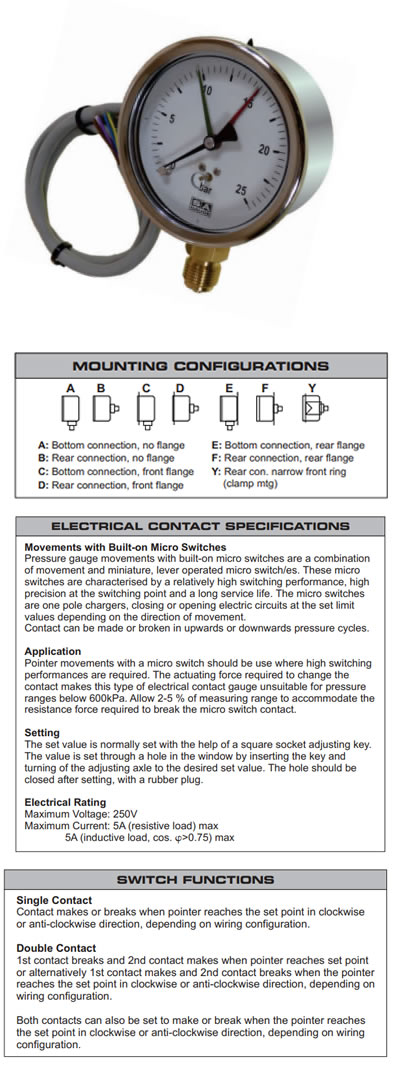

Electrical Contact Micro Switch Type Pressure Gauges |

|

|

Electrical Contact Micro Switch Type Pressure Gauges

Suitable for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be for the control and regulation of industrial processes where switching of electrical circuits are required. Externally adjustable, single or double contacts, attached to the movement of a SA Gauge pressure gauge make the gauge suitable to activate or deactivate electrical devices. Contact can make or break in an upward or downward pressure cycle.

Case Details

Nominal Dia: 100, 160mm S/Steel 304

Bezel

S/Steel rolled ring type - tamper proof. S/Steel 304

Pressure Connection

Material: Type R3: Brass. Type R4: S/Steel 316

Sizes: 1/4", 3/8" & 1/2" in BSP or NPT

Position: See "Mounting Configurations".

Mounting Flange

Material" S/Steel 304 See "Mounting Configurations".

Pressure Ranges

600kPa.... 250MPa (also bar, psi, etc.)

Not suitable for ranges below 600kPa

Pressure Element

Material: Type R3: Cu-alloy. Type R4: S/Steel 316

Pointer

Gauge Pointer: Black

Single Contact Pointer: Red

Double Contact Pointer: Green and red

Dial - Aluminium, white with black lettering.

Window - Plexiglass / polycarbonate.

Weather Protection - IP 54.

Accuracy Class - Class 1

Working Pressure

Steady: Full scale value

Fluctuating: 90% of full scale value

Short Period: 130% of full scale value

For pulsating pressure, the use of an inlet restrictor is

recommended.

Operating Temperature - Ambient: -20 °C to + 60 °C

Medium: +70 °C ( soldered tube ): + 100 °C ( brazed / tig

wellded tube ) For live steam use, a syphon tube is recommended.

Optional Extras - Calibration Certificate

Customized scale plates ( customer logo, red line, etc )

Special Dials, other than standard ( dual scale, bar, psi ),

Colour Coding of dial, Blow out disc, Diaphragm seals

fitted

|

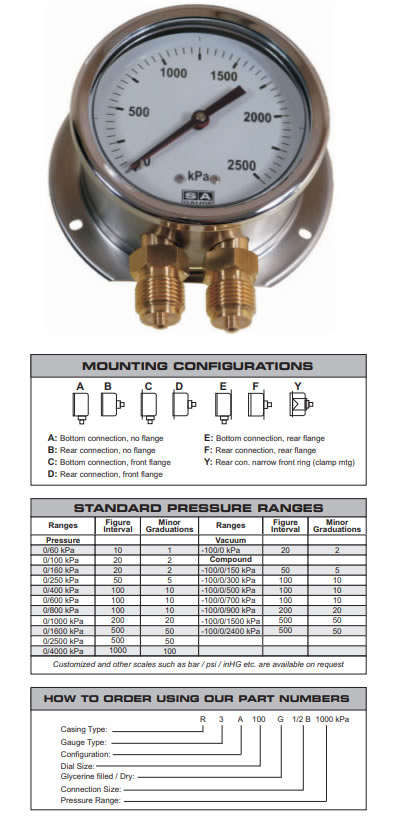

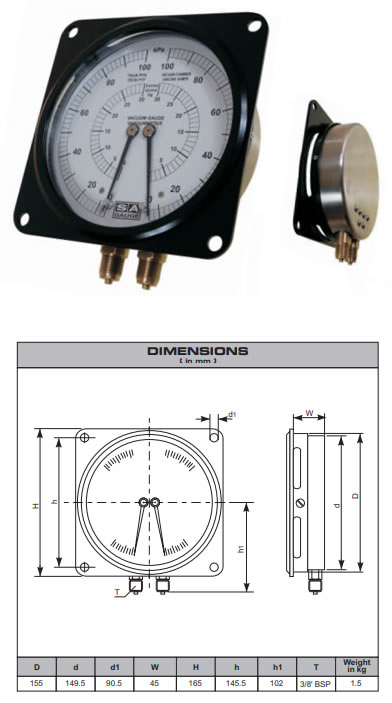

Locomotive Industrial Pressure Gauges |

|

|

Service Intended

Specifically designed duplex gauge for diesel / steam railway and industrial locomotive use. Illumination slots behind the bezel or flange facilitates easy reading in dim environments. Removable front flange available with or without illumination slots.

Case Details

Nominal Dia: 100mm diameter.

Material: Stainless steel 304

Bezel

Material: Stainless steel 304 or mild steel powder coated.

Mounting Configuration

Duplex bottom or rear connection with removable front

flange with or without illumination slots, in stainless

steel or mild steel powder coated.

Pressure Connections

Material: Brass - duplex bottom or rear

Sizes: 3/8" BSP standard, other sizes on request

Pressure Element

Material: Cu-alloy.

Pressure Ranges

-100...6000kPa (also bar, psi, etc.)

Geared Movement

Material: Clockwork brass

Pointer

Collet: Aluminium or brass

Blade: Black or white aluminium depending on dial colour.

Dial

Material: Aluminium, black with white lettering or white with black lettering.

Window

Instrument glass or plexiglass.

Weather Protection

IP 54 Dust resistant.

Working Pressure

Steady: Full scale value

Fluctuating: 90% of full scale value

Short Period: 130% of full scale value

For pulsating pressure, the use of an inlet restrictor and/or damped movement is recommended.

Accuracy Class

Class 1

Operating Temperature

Ambient: -20 °C to + 60 °C

Medium: +70 °C

Optional Extras

Calibration Certificate (Manufacturers)

Calibration Certificate (SANAS)

Customized scale plates ( customer logo, red line, etc )

Special Dials, other than standard ( dual scale, bar, psi )

Colour Coding of dial

Blow out disc |

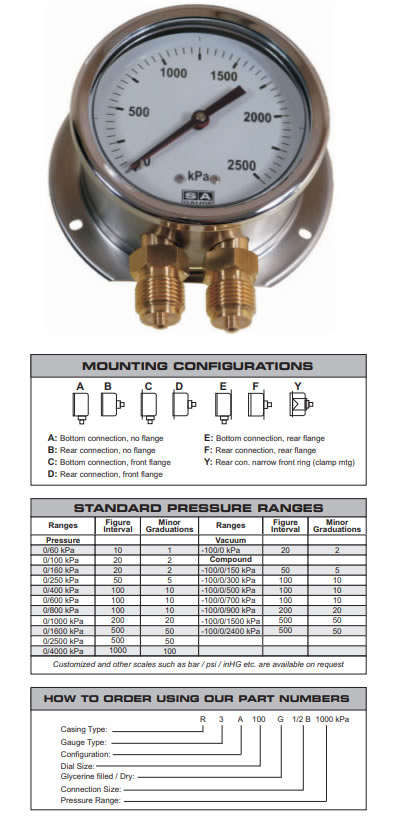

Locomotive RW6 Industrial Pressure Gauges |

|

|

Service Intended

Specifically designed duplex gauge for diesel / steam railway and industrial locomotive use. Illumination slots behind the bezel facilitates easy reading in dim environments. Available with special square, removable front flange, with or without illumination slots.

Case Details

Nominal Dia: 160mm diameter.

Material: Stainless steel 304

Bezel

Material: Stainless steel 304 or mild steel powder coated.

Mounting Configuration

Duplex bottom entry with square, removable front flange, with or without illumination slots, in stainless steel or mild steel powder coated.

Pressure Connections

Material: Brass - duplex

Sizes: 3/8" BSP standard, other sizes on request

Pressure Element

Material: Cu-alloy.

Pressure Ranges

-100...6000kPa (also bar, psi, etc.)

Geared Movement

Material: Clockwork brass

Pointer

Collet: Aluminium or brass

Blade: Black or white aluminium depending on dial colour.

Dial

Material: Aluminium, black with white lettering or white with black lettering.

Window

Instrument glass or plexiglass.

Weather Protection

IP 54 Dust resistant.

Working Pressure

Steady: Full scale value

Fluctuating: 90% of full scale value

Short Period: 130% of full scale value

For pulsating pressure, the use of an inlet restrictor and/or damped movement is recommended.

Accuracy Class

Class 1

Operating Temperature

Ambient: -20 °C to + 60 °C

Medium: +70 °C

Optional Extras

Calibration Certificate (Manufacturers)

Calibration Certificate (SANAS)

Customized scale plates ( customer logo, red line, etc )

Special Dials, other than standard ( dual scale, bar, psi )

Colour Coding of dial Blow out disc |

Safety Industrial Pressure Gauges |

|

|

Service Intended

Safety pressure gauge, with solid front baffle wall, designed with operational safety requirements in mind. Suitable for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be in the chemical, petrochemical, mining, on and offshore process industry.

Case Details

Nominal Dia: 100mm

Material: Stainless steel 304 with solid front baffle wall and blow-out back.

Bezel

Bayonet locking, twist type - removable.

Material: Stainless steel 304

Pressure Connections

Material: Type T3: Brass. Type T4: Stainless steel 316

Sizes: 1/4", 3/8" & 1/2" in BSP or NPT

Position: See "Mounting Configurations".

Mounting Flange

Material: Polished stainless steel 304

Position: See "Mounting Configurations".

Pressure Element

Material:Type T3: Cu-alloy. Type T4: Stainless steel 316

Geared Movement

Material: Clockwork brass or stainless steel.

Pointer

Collet: Aluminium or brass

Blade: Black aluminium

Dial

Material: Aluminium, white with black lettering.

Window

Plexiglass or safety glass.

( Plexiglass recommended for food applications )

Weather Protection

IP 65 Dust & weather proof.

Working Pressure

Steady: Full scale value

Fluctuating: 90% of full scale value

Short Period: 130% of full scale value

For pulsating pressure, the use of an inlet restrictor and/or liquid filling is recommended.

Accuracy Class

Class 1

Operating Temperature

Ambient: -20 °C to + 60 °C

Medium: +70 °C ( soldered tube ): + 100 °C ( brazed / tig

wellded tube ) For live steam use, a syphon tube is

recommended.

Optional Extras

Calibration Certificate

Customized scale plates ( customer logo, red line, etc )

Special Dials, other than standard ( dual scale, bar, psi )

Damped movement ( Vibragauge )

Colour Coding of dial

Drag pointer ( maximum set pointer )

Micro adjustable pointer

Diaphragm seals fitted |

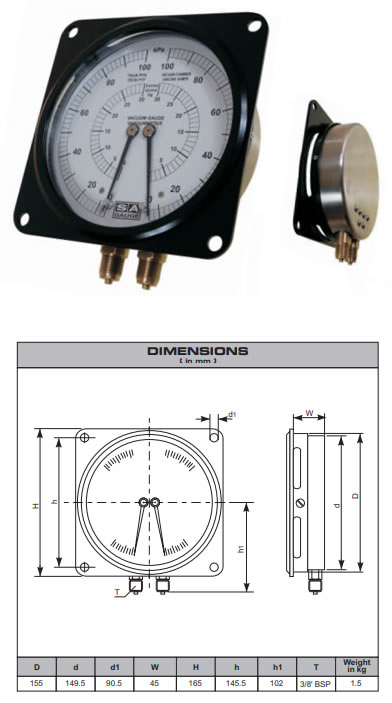

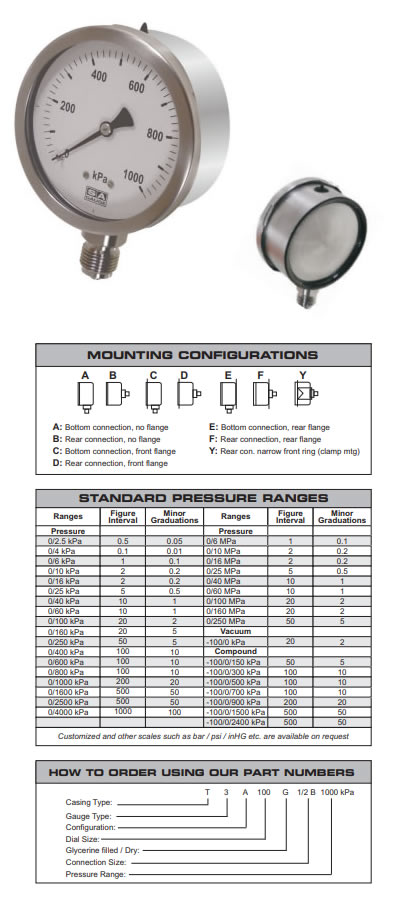

Duplex Industrial Pressure Gauges |

|

|

Service Intended

Suitable for the measurement and indication of two simultaneous or individually applied pressures. Intended for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system.

Case Details

Nominal Dia: 100, 160mm

Material: Stainless steel 304

Bezel

S/Steel 304 rolled ring type - tamper proof.

Pressure Connections

Material: Type 3: Brass. Type 4: Stainless steel 316

Sizes: 1/4", 3/8" & 1/2" in BSP or NPT

(Position: See "Mounting Configurations".)

Mounting Flange

Material: Polished stainless steel 304

Pressure Element

Material: Type 3: Cu-alloy. Type 4: Stainless steel 316

Geared Movement

Material: Clockwork brass or stainless steel.

Pointer

Collet: Aluminium or brass Blade: Black aluminium

Dial

Material: Aluminium, white with black lettering.

Window

Instrument glass or plexiglass

Weather Protection

IP 65 Dust & weather proof.

Working Pressure

Steady: Full scale value

Fluctuating: 90% of full scale value

Short Period: 130% of full scale value

For pulsating pressure, the use of an inlet restrictor and/or liquid filling is recommended.

Accuracy Class

Class 1

Operating Temperature

Ambient: -20 °C to + 60 °C

Medium: +70 °C ( soldered tube ): + 100 °C ( brazed / tig welded tube )

Optional Extras

Calibration Certificate

Customized scale plates ( customer logo, red line, etc )

Special Dials, other than standard ( dual scale, bar, psi )

Colour Coding of dial Blow out disc |

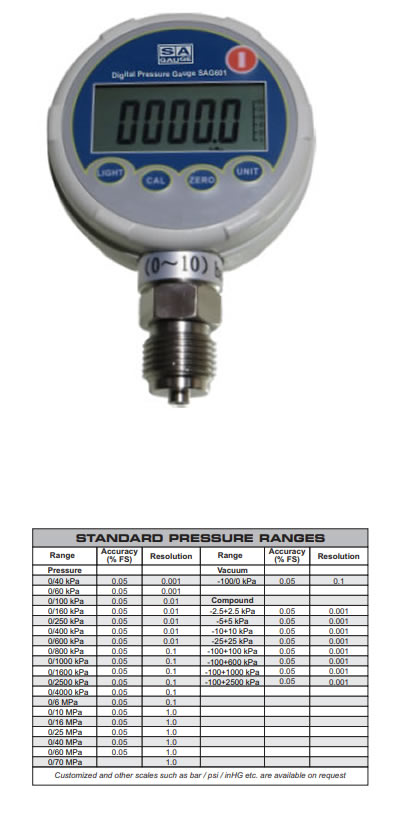

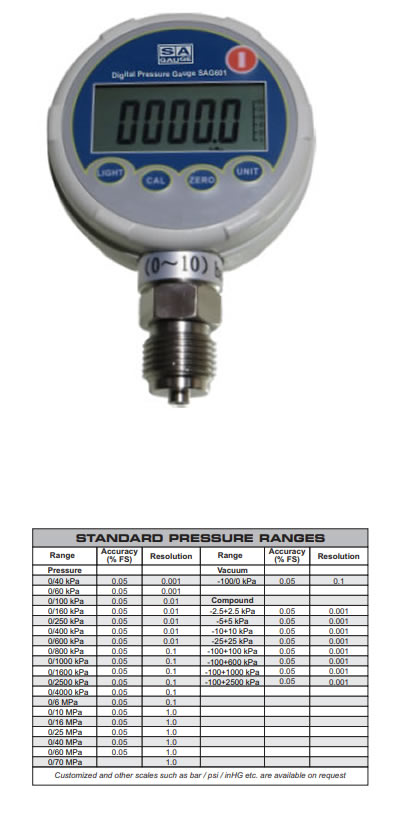

Digital Industrial Pressure Gauges |

|

|

Service Intended

High accuracy digital gauge, suitable for media such as air, water, oil & gases that do not attack stainless steel parts or will obstruct the pressure system. Typical applications will be in the general industrial, petroleum, chemical and laboratory industry.

Features

Low power consumption, 1 year continuously.

Pressure bar graph providing quick visual indication of

pressure output.

Zero and full scale calibration function.

Overload alarm function

CE and EX approved

Case & Bezel Details

Nominal Dia: 94mm x 40mm deep

Material: Rugged aluminium alloy, coated.

Pressure Connections

Material: Stainless steel 316

Sizes: 1/2" BSP Standard (other on request)

Technical Specifications

Accuracy: +/- 0.05% Full Scale

Pressure Range: As per standard ranges in chart

2 Display units: pa, kPa, MPa, mbar, bar, psi, kgf/cm ,

mmH O and mmHg 2

Display: 5 digit LCD with backlight function, 14mm

character height

Temperature Compensation: 0+50 C

Temperature Stability: 0.02% FS/ C

Operational Spec: Ambient Temp 0+50 C

Medium Temp 0+70 C

Relative Humidity: 0-85% non-condensing

Burst Pressure: 2 x FS

Over Pressure: 1.7x FS@<35MPa, 1.5x FS@>35MPa

Wetted Parts: Stainless Steel 316

Power: 1pc disposable 3.6V dc lithium battery

Weight: 0.5kg

Optional Extras

Calibration Certificate

Diaphragm Seals fitted |

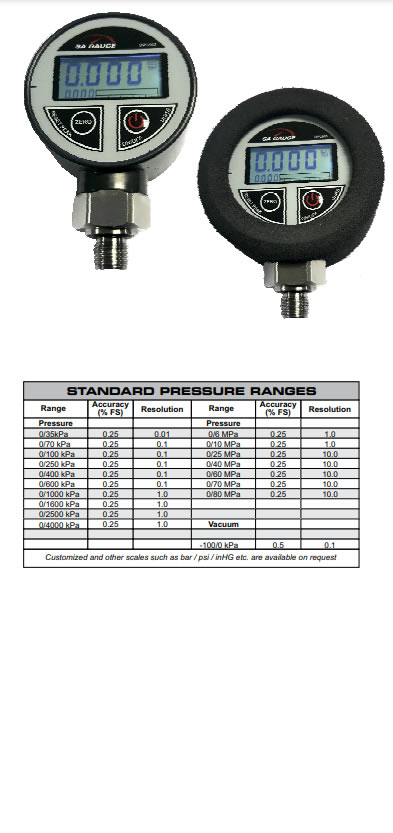

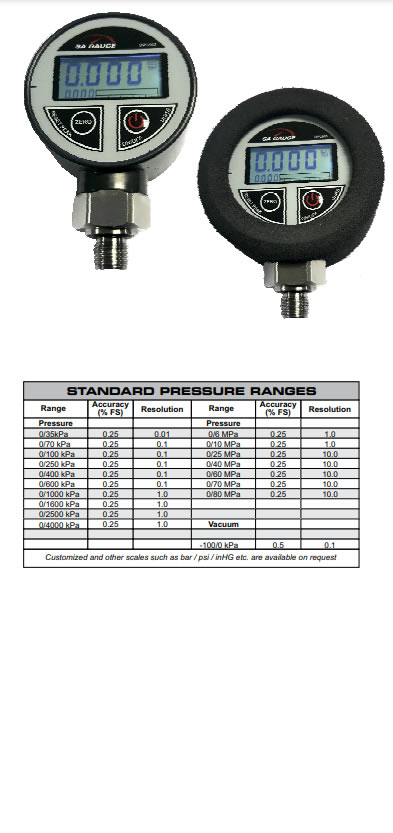

Digital Industrial Pressure Gauges |

|

|

Service Intended

General purpose digital gauge, suitable for media such as air, water, oil & gases that do not attack stainless steel parts or will obstruct the pressure system. Typical applications will be in the and general industrial hydraulic industry.

Description

The DPG 502 is a digital pressure gauge with an accuracy of 0.2% of full scale. it features a max/peak pressure memory function.

Features

Low power consumption, 1200 hours battery life.

High accuracy and stability.

(Peak) Maximum value function.

Zero and full scale calibration function.

Case Dimension

Nominal Dia: mm x mm deep 67 35

Pressure Connections

Material: Stainless steel 316

Sizes: 1/4" BSP Standard (other on request)

Technical Specifications

Accuracy : +/- 0.25% Full Scale

Pressure Range : As per standard ranges in chart

Pressure units : kPa, MPa, bar, psi and kg/cm2

Display : digit LCD , 4 with back light

Digit Dimensions : 12 digit mm height

Bar Graph : Percentage of full scale

Battery Status : Condition display - 5 segments

Sampling Rate : 4 times per second

Memory : Max pressure vaule

Auto Power : Selectable 1-15 min

Zero Function : zero reset and adjustment

Reset: : Delete max/peak value

Temp Compensation: -10+70 Co

Temp Stability : 0.05% FS/ Co

Operational Spec : Ambient Temp -10+60 Co

Medium Temp -10+80 Co

Relative Humidity : 0-90% non-condensing

Burst Pressure : 3 x FS

Over Pressure : x FS 1.5

Wetted Parts : Stainless Steel 316

Power : V battery ( ) 9 6LR61

Weight : 0. kg 25

Optional Extras

Calibration Certificate

Diaphragm Seals fitted

Rubber Cover |

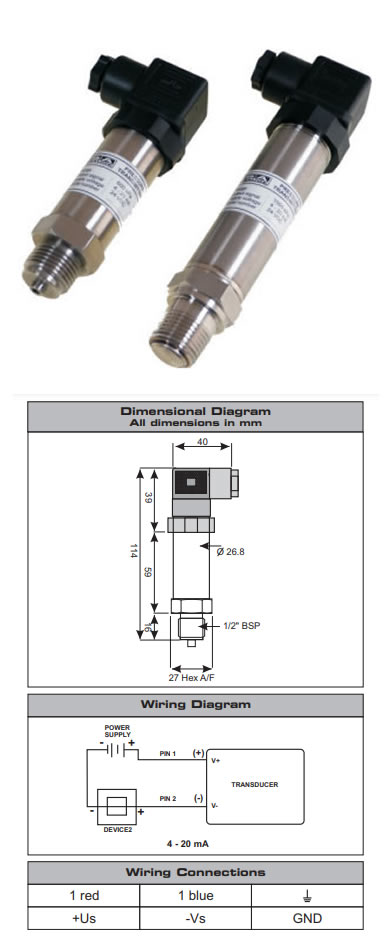

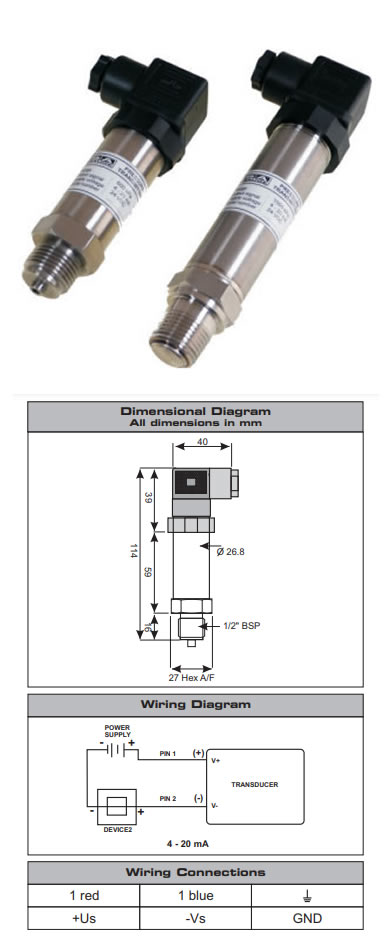

Industrial Pressure Transmitters |

|

|

Service Intended

Suitable for the majority of general industrial control applications such as hydraulics, pneumatics, pharmaceutical and food & beverage.

Construction

Material: Stainless steel 316

Wetted Parts; Stainless steel 316

Flush diaphragm for type PT2: Stainless steel 316

Pressure Connections

Material: Stainless steel 316

Size: 1/2" BSP

Ingress Protection

IP 65

Working Pressure

Steady: Full scale value

Over Range Limit: 150% of FS

Burst Pressure: 3 x FS

Signal Output

4 - 20 mA 2-wire

Power Supply

10 - 30 V DC

Accuracy Class

0.5% (0.25% optional)

Compensated Temperature Range

0 to 85 °C

Temperature Error: Zero and span < 0.02% FS / K

Installation

Careful consideration, regarding process conditions, should be taken when installing transmitters. Damage to the transmitter may be caused by excessive vibration, pulsation, temperature or over pressure. A capillary assembly fitted to the transmitter to remove

the transmitter from the above conditions may increase instrument life. Fluid hammer, surges or pressure spikes must be avoided by fitting a suitable snubbing device.

Typical symptoms of damage:

- The transmitter will indicate an output at zero pressure

- The transmitter output remains constant while pressure is applied or no output is indicated at all.

Zero and Span Adjustment

Zero and span adjustment is not normally required but may be done on site to trim offsets in the process system. Although field calibratable we recommend that the instrument be returned to the factory for the necessary adjustments as proper re-calibration requires a calibration standard at least 3 x more accurate than the accuracy of the transmitter. Individual span or zero adjustment may also have an effect on each other.

Optional Extras

Calibration certificate

Diaphragms seals fitted

Due to continuou |

Pressure Testing Kits |

|

|

Pressure Testing Kits

TAS distributes easy to handle, robust testing kits designed for troubleshooting on hydraulic, air and vacuum systems. Sizes and configurations other than indicated below are also available on request.

Portable pressure testing kits designed for fault finding on hydraulic, pneumatic and vacuum systems.

- TKS, TKM, TKL series: Rectangular, powder

coated carry case in lightweight metal, with your

selection of pressure ranges. Each gauge with

its own test point.

- TKQ series: Round s/steel carry case with

hanger hook or magnetic back. Three gauges

working as one. One pressure test point, auto

switching between ranges.

|

Mechanical Pressure Gauges (20P/25P Series) |

|

|

The 20P Series (2 inch/51 mm dial) and the 25P Series (2-1/2 inch/64 mm dial) Swichgage models are diaphragm-actuated, pressure-indicating gages with built-in electrical switches. These switches are used for tripping alarms and/or shutdown devices.

Ranges are available from 0-15 psi (103 kPa) [1.0 bar] through 0-100 psi (690 kPa) [7.0 bar].

The gage mechanism is enclosed in a steel case coated to resist corrosion. A polycarbonate, break-resistant lens and a polished, stainless steel bezel help protect this rugged, built-to-last instrument. Accuracy and protection from moderate overpressure is assured by a unique, unitized diaphragm chamber. A built-in pulsation dampener helps eliminate pointer flutter and is removable for cleaning. For models 20P and 25P, the gage pointer acts as a pressure indicator and as one switch pole which completes a circuit when it touches the adjustable limit contact. Contacts are grounded through the case and have self-cleaning motion to ensure electrical continuity.

Model 20PE has internal snap-acting SPDT switches. Gage-only models, without the switches (Murphygage®) are also available.

Base Models

20P and 25P Series Swichgage

The gage pointer makes with an adjustable contact to complete a pilot-duty circuit.

20PE Swichgage

20PE (was 20EO)

Features internal snap-acting SPDT switches, instead of the single pole/pointer contacts. When the switch closes on falling pressure, it becomes set, as pressure rises the switch resets.

20P7 Lockout Swichgage

Same as 20P Series. They also include a front, semi-automatic lockout for startup override. This built-in device holds the pointer away from the contact on startup. When pressure exceeds the set point, the lockout is automatically disengaged (see following pages for details).

20PG Murphygage

Gage without contact(s) |

Mechanical Pressure Gauges (25DP and A25DP) |

|

|

The 25DP and A25DP Series (2-1/2 inch/64 mm dial) Swichgage instruments are diaphragm-actuated, differential pressure-indicating gages with a built-in electrical switch. This switch is used for tripping alarms and/or shutting down equipment. These gages are intended to monitor and indicate oil, fuel or water filter restriction and can reduce the risk of dangerously high pressure which may rupture the filter, resulting in contaminants entering the system.

The 25DP series mechanism is enclosed in a steel case coated to resist corrosion. The A25DP series has a polycarbonate case sealed from the environment. Both feature a polycarbonate, break-resistant lens to help protect the instruments.

The gage pointer acts as a pressure indicator and as one switch pole which completes a circuit when it touches the adjustable limit contact. Contacts have self-cleaning motion to ensure electrical continuity.

Additional features:

Constant visual indication of the condition of your filter is shown on the dial. Two instruments in one with an accurate indicating gage and adjustable p.s.i.d. limit switch reduces inventory and installation time. Adjustable contact lets you set the monitoring range of the gage. The contact is tamper proof and can be set only with a 1/16 Allen-head wrench. All gages are made of durable materials allowing them to withstand rugged applications. Early filter changes cost you money and increase the risk of contaminants entering the system. A filter restriction Swichgage instrument will let you know when to change the filter and maintain peak efficiency.

Base Models

25DP and A25DP Swichgage instrument

The gage pointer makes with an adjustable contact to complete a pilot-duty circuit. |

Mechanical Pressure Gauges (A20P / A25P Series) |

|

|

The A20 Series (2 inch/51 mm dial) and the A25 Series (2-1/2 inch/64 mm dial) Swichgage instruments are diaphragm-actuated, pressure-indicating gages with built-in electrical switches for tripping alarms and/or shutdown devices.

Ranges are available from 0-30 psi (207 kPa) [2.0 bar] through 0-300 psi (2.1 MPa) [20 bar].

These rugged, instruments are face sealed from the environment by the unique combination of a polycarbonate case and lens, a polished stainless steel bezel and O-ring seals. Tese gages are sealed from the external environment. Accuracy and protection from moderate overpressure is assured by a unique, unitized diaphragm chamber. A built-in pulsation dampener helps eliminate pointer flutter and is removable for cleaning.

For series A25P, the gage pointer acts as a pressure indicator and as one switch pole which completes a circuit when it touches the adjustable limit contact. Contacts have self-cleaning motion to ensure electrical continuity.

Model A20PE has internal snap-acting SPDT switches for three wire control and can be wired to make or to break a circuit.

Gage-only models, without switches (Murphygage instrument) are also available.

A20/A25 Series applications include: engines/equipment in oil field for lube oil pressure, water pump pressure, hydraulic pressure, air pressure, etc.

Base Models

A25P Series Swichgage

The gage pointer makes with an adjustable contact to complete a pilot duty circuit.

A20PE Swichgage

A20PE (was A20EO). Features internal snap-acting SPDT switches, instead of the single pole/pointer contacts. When the switch closes on falling pressure, it becomes set, as pressure rises the switch resets (refer to wiring diagram).

A20PG Murphygage instrument

Gage without contact(s) |

Mechanical Pressure Gauges (45APE Series) |

|

|

The 45APE Series gage instrument is a mechanical gage for pressure indication. It includes two adjustable SPDT switches. These snap-acting switches can be used for start and stop, to trip alarms and to shut down equipment. Ranges are available from 30 psi (207 kPa) [2.06 bar] thru 5,000 psi (34.48 MPa) [344.73 bar].

The 45APE Series utilizes a bourdon tube sensing unit with a stainless steel dual-sector geared movement. Each of the sectors drives separate pointers when pressure is applied to the bourdon tube. The indicating pointer (visible pointer) shows actual pressure reading, including below and beyond the low and high trip points. The low and high trip points are adjustable independently on the gage front lens. The switch operator pointer (behind the dial) is calibrated to follow the indicating pointer. The low and high trip point indicators arrest the switch operator pointer. As pressure decreases or increases through the principal of lost motion, the respective snapswitch is tripped.

The 45APE Series models are widely used in applications requiring pressure indication and Form C low and high pressure switches.

Basic Models

45APE Series gage instrument

Surface mount (square case) version

45APEF Series gage instrument

Panel Mount (round Case) Version

- Combination Indicating Gage with Independent Low and High Snap-Acting Switches

- Field-Adjustable and Highly Visible Low and High Pressure Trip Point Indicators

- Dual-Sector Geared Movement Allows for Full-Scale Indication and Set Point Control

- Panel and Surface Mount Versions Available

- Latching Control Relay Versions Available

|

Mechanical Pressure Gauges OPL Series |

|

|

The OPL-series pressure gage instruments are combination pressure indicating gages with adjustable low and high limit switches. Limit switches can be wired directly to electric pilot circuits to operate alarms, shutdown or the start/stop of engines and electric motors. Surface mount or panel mount enclosure is available for most versions. All versions feature a 4-1/2 in. (114 mm) dial for easy viewing. Adjustable limit switches are accessible from the front of the gage. Limit contacts have self-cleaning motion to enhance electrical continuity.

- Combination Indicating Gage and Critical Pressure Limit Switches

- High and Low Pressure Limit Contacts Are Visible and Adjustable

- Panel and Surface Mount Versions

- Indicating-only Gage Available

- Latching Control Relay Versions Available

|

Pressure Sensors and Instruments PD8100 Series |

|

|

The PD8100 Series eliminates pointer flutter on pressure indicating gage devices which are subject to pulsating pressure from reciprocating pumps or compressors. It also allows a close setting of high and low contact points providing for more accurate pressure indication and control of equipment.

The PD8100 Series decreases wear on geared movements and increases the life of pressure indicating instruments by eliminating excessive gage strain and unnecessary movement, a necessity which quickly pays for itself by protecting any pressure indicating and control instrument which is subject to pulsation.

PD8100 SERIES IS NOT FOR USE ON OXYGEN OR LIQUID OXYGEN APPLICATIONS.

The PD8100 is quality built with a large diameter valve stem wheel for ease of adjustment and features clearly printed operating instructions.

Machined from 1 3/8-inch (35 mm) hex bar stock, a two degree taper on the valve and stem assure positive dampening.

It’s available in brass, carbon steel, 303 stainless steel or 316 stainless steel to meet pressure and environmental requirements with either 1/2 NPT or 1/4 NPT inlet connections.

- Used on Controllers, Instruments and Recorders to Dampen Pressure Pulsation

- Eliminate Gage Pointer Flutter

- Aids in Providing More Accurate Pressure Indication

- Decreases wear on a Gage’s Geared Movement

|

Mechanical Pressure Gauges PT167EX |

|

|

The FW Murphy PT167EX is a pressure gage instrument connected to a threaded pressure diaphragm housing. The gage is enclosed in an explosion-proof case and is CSA rated for Class I, Division 1, Groups C and D.

The PT167EX is a pressure-indicating gage with adjustable low and high pressure limit switches. When the gage pointer touches the low or high limit switches, an electrical circuit is completed which can operate alarms and/or shut down equipment.

The 2 NPT, sealed diaphragm housing is attached directly to the gage connection. The diaphragm housing is filled with a silicone fluid so that pressure against the diaphragm causes the gage to respond. The housing seals the sensing element from the medium being measured.

Applications include highly viscous liquids such as crude oil on lead line applications. Other applications have included asphalt, sludge, abrasive materials, etc. |

Pressure Senders |

|

|

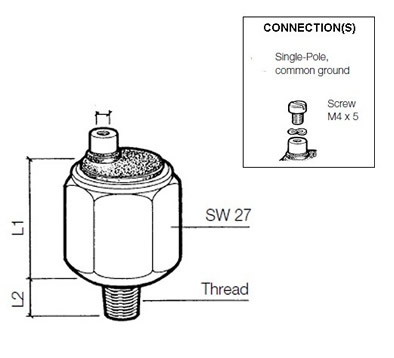

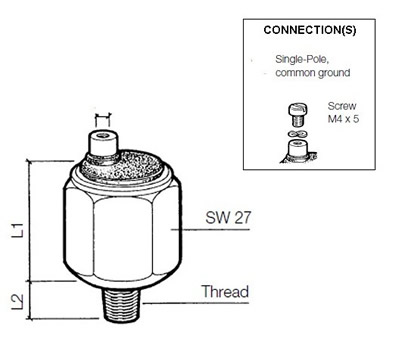

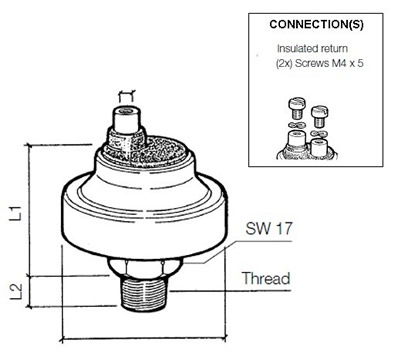

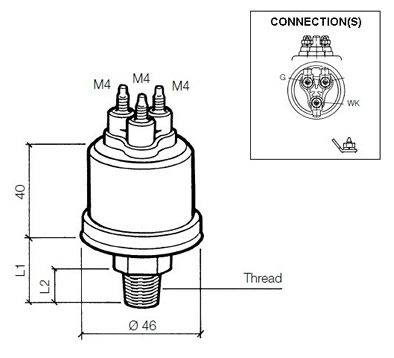

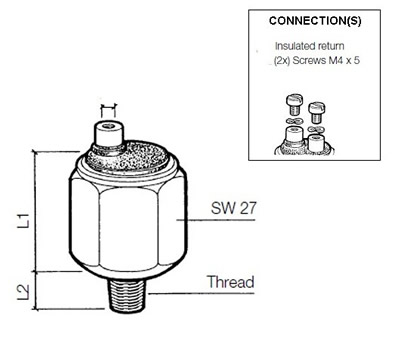

Pressure sender 0-10 Bar

Part-number:

VDO 362-081-003-002K

- Pressure range: 0 to 10 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 5 - 90 Ohm

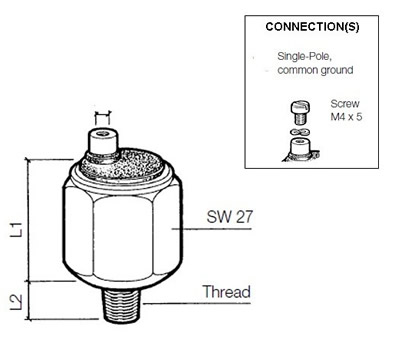

- Sensor signal: 1-pole common ground - 2 station

- No warning contact

|

Pressure senders 0-10 Bar |

|

|

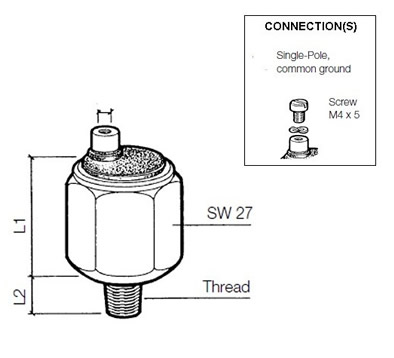

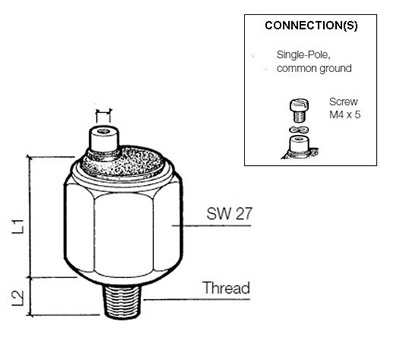

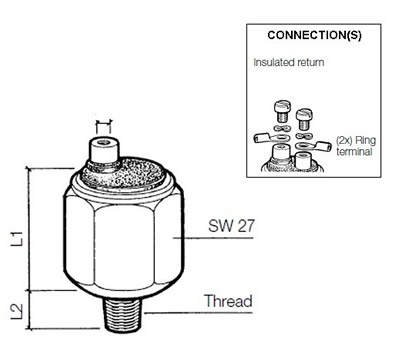

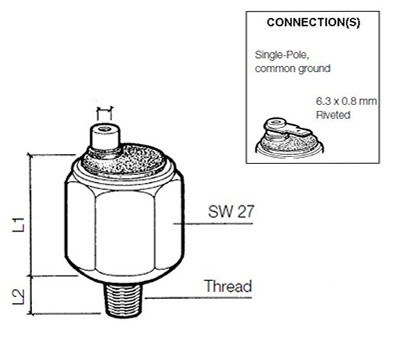

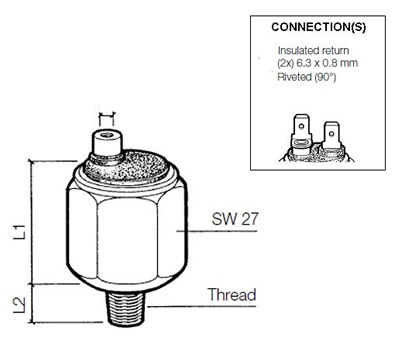

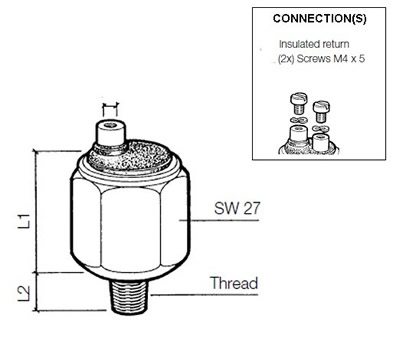

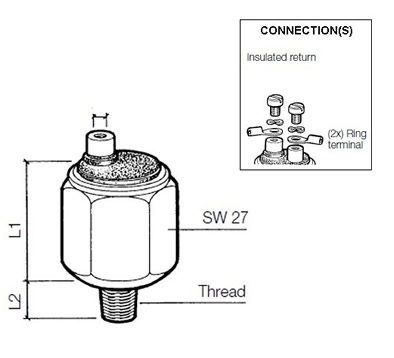

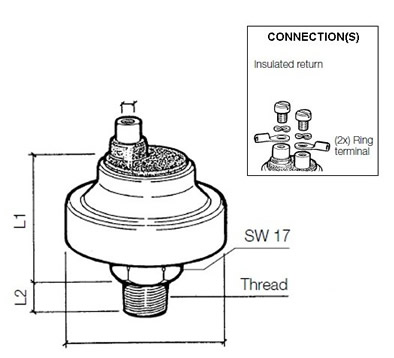

VDO Pressure sender 0-10 Bar - R1/8 DIN 2999

Part-number:

VDO 360-081-032-057C

- Pressure range: 0 to 10 Bar

- Thread: R1/8 DIN 2999

- Sender resistance range: 10 - 184 Ohm

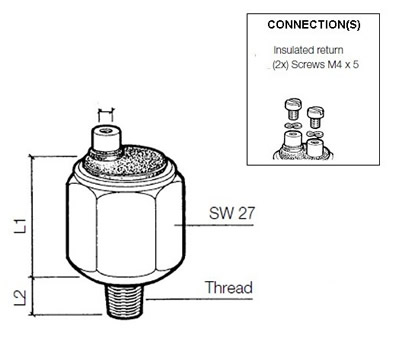

- Sensor signal: 2-pole insulated return

- No warning contact

|

Pressure senders 0-10 Bar |

|

|

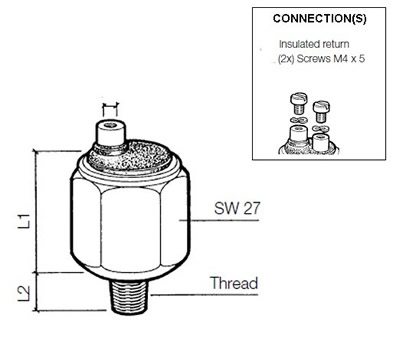

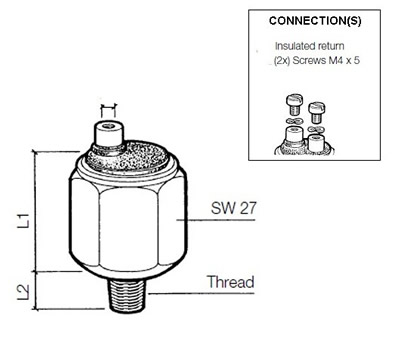

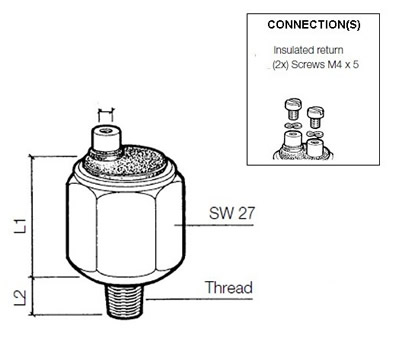

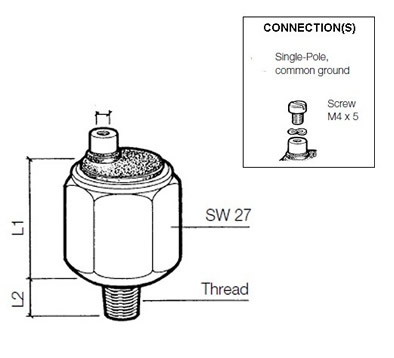

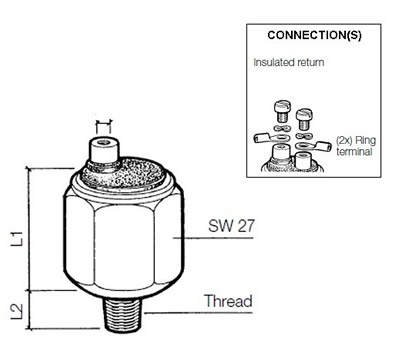

VDO Pressure sender 0-10 Bar - 1/4-18 NPTF

Part-number:

VDO 360-081-029-020C

- Pressure range: 0 to 10 Bar

- Thread: 1/4 - 18 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure senders 0-10 Bar |

|

|

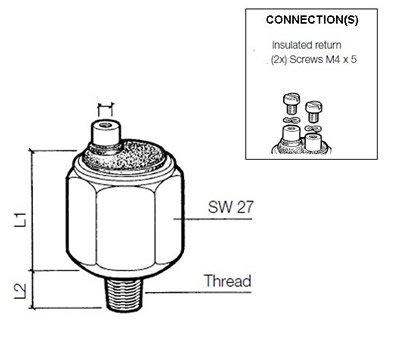

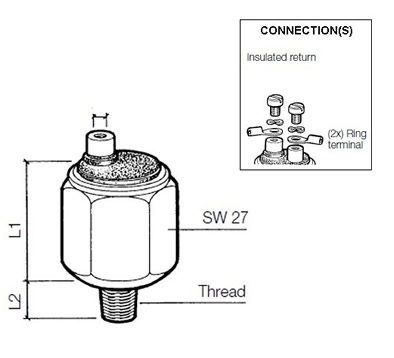

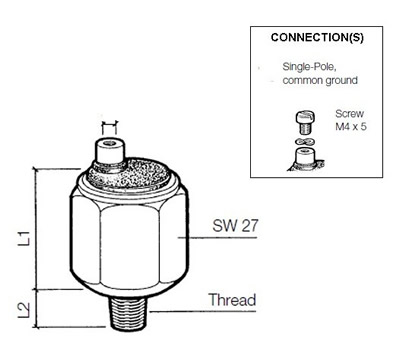

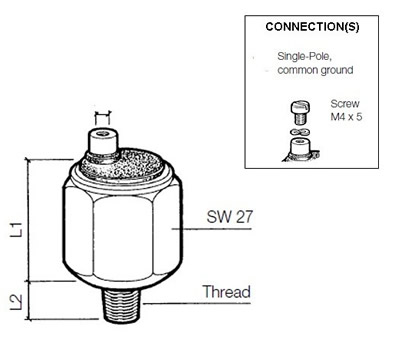

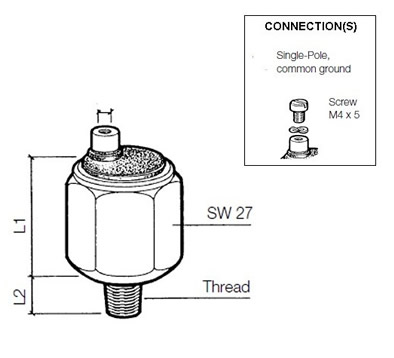

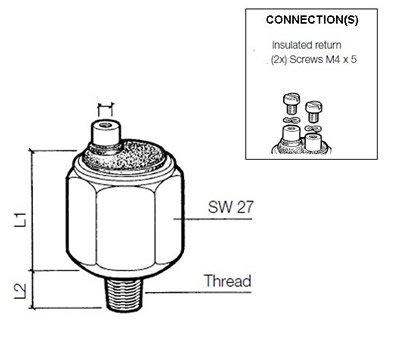

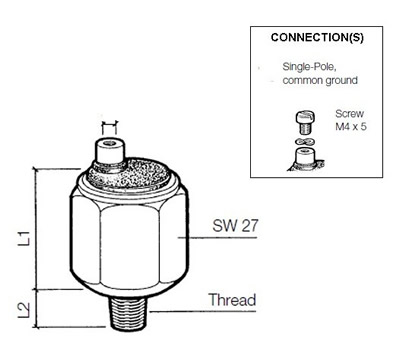

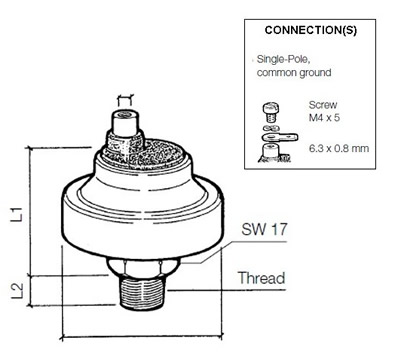

VDO Pressure sender 0-10 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-032-067C

- Pressure range: 0 to 10 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- Replacing product on request

|

Pressure senders 0-10 Bar - M12 |

|

|

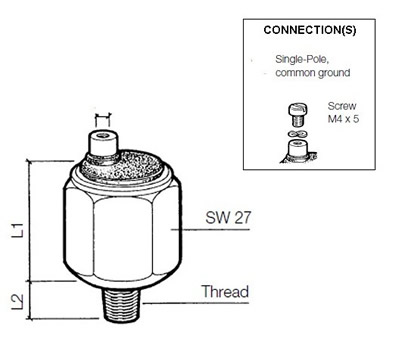

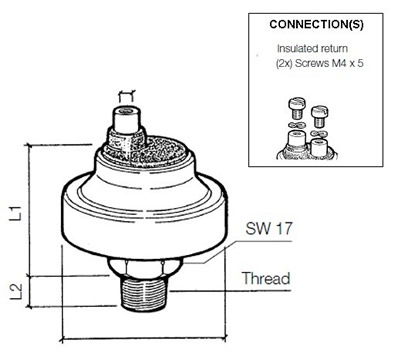

VDO Pressure sender 0-10 Bar - M12

Part-number:

VDO 360-081-061-006C

- Pressure range: 0 to 10 Bar

- Thread: M12 x 1.5 Conical short

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- Warning contact: 5.00 Bar ± 0.30 Bar

|

Pressure senders 0-10 Bar - M12 |

|

|

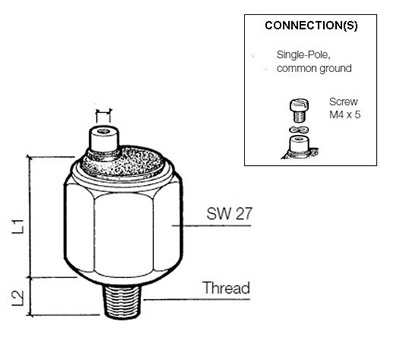

VDO Pressure sender 0-10 Bar - M12

Part-number:

VDO 360-081-063-001C

- Pressure range: 0 to 10 Bar

- Thread: M12 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- Warning contact: 5.20 Bar ± 0.30 Bar

|

Pressure sender 0-10 Bar |

|

|

VDO Pressure sender 0-10 Bar - M14

Part-number:

VDO 360-081-062-003C

- Pressure range: 0 to 10 Bar

- Thread: M14 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- Warning contact: 5.50 Bar ± 0.30 Bar

|

Pressure sender 0-10 Bar - M14 |

|

|

VDO Pressure sender 0-10 Bar - M14

Part-number:

VDO 360-081-039-007C

- Pressure range: 0 to 10 Bar

- Thread: M14 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- Warning contact: 1.00 Bar ± 0.15 Bar

|

Pressure sender 0-10 Bar – 1/8-27 NPTF |

|

|

VDO Pressure sender 0-10 Bar – 1/8-27 NPTF

Part-number:

VDO 360-081-039-003C

- Pressure range: 0 to 10 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- Warning contact: 0.80 Bar ± 0.15 Bar

|

Pressure sender 0-16 Bar |

|

|

VDO Pressure sender 0-16 Bar - M12

Part-number:

VDO 360-081-037-019C

- Pressure range: 0 to 16 Bar

- Thread: M12 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure sender 0-16 Bar M14 |

|

|

VDO Pressure sender 0-16 Bar - M14

Part-number:

VDO 360-081-038-014C

- Pressure range: 0 to 16 Bar

- Thread: M14 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- No warning contact

|

Pressure sender 0-16 Bar - M18 |

|

|

VDO Pressure sender 0-16 Bar - M18

Part-number:

VDO 360-081-063-003C

- Pressure range: 0 to 16 Bar

- Thread: M18 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- Warning contact: 5.50 Bar ± 0.30 Bar

|

VDO Pressure sender 0-2 Bar |

|

|

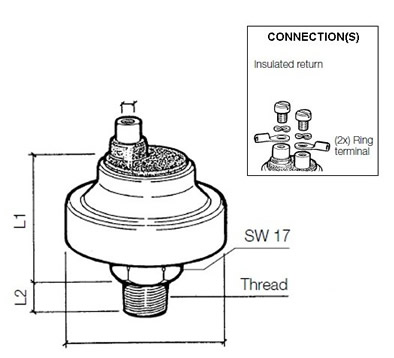

VDO Pressure sender 0-2 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-032-025C

- Pressure range: 0 to 2 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- No warning contact

|

Pressure sender 0-2 Bar - M18 |

|

|

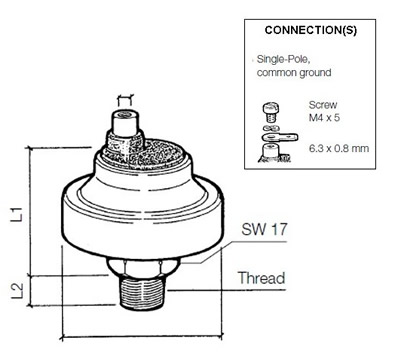

VDO Pressure sender 0-2 Bar - M18

Part-number:

VDO 360-081-032-058C

- Pressure range: 0 to 2 Bar

- Thread: M18 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- No warning contact

|

Pressure sender 0-25 Bar |

|

|

VDO Pressure sender 0-25 Bar

Part-number:

VDO 360-081-037-010C

- Pressure range: 0 to 25 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure sender 0-25 Bar - NPTF |

|

|

VDO Pressure sender 0-25 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-038-003C

- Pressure range: 0 to 25 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- No warning contact

|

Pressure sender 0-25 Bar |

|

|

VDO Pressure sender 0-25 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-053-001C

- Pressure range: 0 to 25 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- Warning contact: 15.5 Bar + 1.5 Bar

|

Pressure sender 0-25 Bar - 1/8-27 NPTF |

|

|

VDO Pressure sender 0-25 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-053-004C

- Pressure range: 0 to 25 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- Warning contact: 14.5 Bar + 1.5 Bar

|

Pressure sender 0-28 Bar |

|

|

VDO Pressure sender 0-28 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-038-008C

- Pressure range: 0 to 28 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure sender 0-3 Bar |

|

|

VDO Pressure sender 0-3 Bar - M12

Part-number:

VDO 360-081-029-087C

- Pressure range: 0 to 3 Bar

- Thread: M12 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure sender 0-3 Bar |

|

|

VDO Pressure sender 0-3 Bar - M12

Part-number:

VDO 360-081-052-003C

- Pressure range: 0 to 3 Bar

- Thread: M12 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure sender 0-30 Bar |

|

|

VDO Pressure sender 0-30 Bar - M18

Part-number:

VDO 360-081-054-002Z

- Pressure range: 0 to 30 Bar

- Thread: M18 x 1.5

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- No warning contact

|

Pressure sender 0-5 Bar |

|

|

VDO Pressure sender 0-5 Bar - 1/4-18 NPTF

Part-number:

VDO 360-081-029-008C

- Pressure range: 0 to 5 Bar

- Thread: 1/4 - 18 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure sender 0-5 Bar - 1/4-18 NPTF |

|

|

VDO Pressure sender 0-5 Bar - 1/4-18 NPTF

Part-number:

VDO 360-081-032-016C

- Pressure range: 0 to 5 Bar

- Thread: 1/4 - 18 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- No warning contact

|

Pressure sender 0-5 Bar - 1/8-27 NPTF |

|

|

VDO Pressure sender 0-5 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-029-041C

- Pressure range: 0 to 5 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 1-pole common ground

- No warning contact

|

Pressure sender 0-5 Bar - 1/8-27 NPTF |

|

|

VDO Pressure sender 0-5 Bar - 1/8-27 NPTF

Part-number:

VDO 360-081-039-015C

- Pressure range: 0 to 5 Bar

- Thread: 1/8 - 27 NPTF

- Sender resistance range: 10 - 184 Ohm

- Sensor signal: 2-pole insulated return

- Warning contact: 0.25 Bar ± 0.15 Bar

|

Pressure switches |

|

|

VDO Pressure switch 0.30 Bar - M14

Part-number:

VDO 230-112-007-005C

- Pressure switchpoint: 0.30 Bar ± 0.15 Bar

- Thread: M14 x 1.5

- Contact open as pressure rises

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 0.40 Bar |

|

|

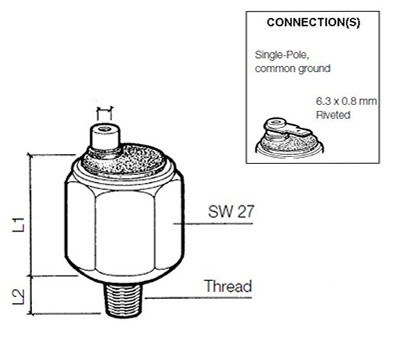

VDO Pressure switch 0.40 Bar - M10

Part-number:

VDO 230-112-001-004C

- Pressure switchpoint: 0.40 Bar ± 0.30 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure rises

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|

Pressure switch 0.50 Bar |

|

|

VDO Pressure switch 0.50 Bar - M10

Part-number:

VDO 230-112-003-015C

- Pressure switchpoint: 0.50 Bar ± 0.10 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|

Pressure switch 0.50 Bar |

|

|

VDO Pressure switch 0.50 Bar - M10

Part-number:

VDO 230-112-005-006C

- Pressure switchpoint: 0.50 Bar ± 0.20 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 0.80 Bar |

|

|

VDO Pressure switch 0.80 Bar - M10

Part-number:

VDO 230-112-005-005C

- Pressure switchpoint: 0.80 Bar ± 0.20 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 0.40 Bar |

|

|

VDO Pressure switch 0.90 Bar - M10

Part-number:

VDO 230-112-001-015C

- Pressure switchpoint: 0.90 Bar ± 0.15 Bar

- Thread: M10 x 1 Tapered short

- Contact open as pressure falls

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|

Pressure switch 1.00 Bar |

|

|

VDO Pressure switch 1.00 Bar - M10

Part-number:

VDO 230-112-001-001C

- Pressure switchpoint: 1.00 Bar ± 0.20 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure rises

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|

Pressure switch 1.20 Bar |

|

|

VDO Pressure switch 1.20 Bar - M10

Part-number:

VDO 230-112-005-012C

- Pressure switchpoint: 1.20 Bar ± 0.20 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 1.50 Bar |

|

|

VDO Pressure switch 1.50 Bar - M10

Part-number:

VDO 230-112-005-011C

- Pressure switchpoint: 1.50 Bar ± 0.20 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 1.80 Bar |

|

|

VDO Pressure switch 1.80 Bar - M10

Part-number:

VDO 230-112-005-003C

- Pressure switchpoint: 1.80 Bar ± 0.20 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 10.00 PSI |

|

|

VDO Pressure switch 10.00 PSI - 1/8-27 NPTF

Part-number:

VDO 230-112-003-013C

- Pressure switchpoint: 10.00 PSI ± 2.00 PSI

- Thread: 1/8 - 27 NPTF

- Contact close as pressure falls

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|

Pressure switch 10.50 Bar |

|

|

VDO Pressure switch 10.50 Bar - 1/8-27 NPTF

Part-number:

VDO 230-213-002-003C

- Pressure switchpoint: 10.50 Bar ± 0.30 Bar

- Thread: 1/8 - 27 NPTF

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 12.00 Bar |

|

|

VDO Pressure switch 12.00 Bar - 1/8-27 NPTF

Part-number:

VDO 230-213-001-011C

- Pressure switchpoint: 12.00 Bar ± 0.40 Bar

- Thread: 1/8 - 27 NPTF

- Contact close as pressure falls

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|

Pressure switch 12.50 Bar |

|

|

VDO Pressure switch 12.50 Bar - M14

Part-number:

VDO 230-213-004-002C

- Pressure switchpoint: 12.50 Bar ± 0.40 Bar

- Thread: M14 x 1.5

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Replacing product on request

|

Pressure switch 2.00 Bar |

|

|

VDO Pressure switch 2.00 Bar - M10

Part-number:

VDO 230-112-004-004C

- Pressure switchpoint: 2.00 Bar ± 0.20 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|

Pressure switch 3.00 Bar |

|

|

VDO Pressure switch 3.00 Bar - M10

Part-number:

VDO 230-112-005-004C

- Pressure switchpoint: 3.00 Bar ± 0.40 Bar

- Thread: M10 x 1 Tapered short

- Contact close as pressure falls

- Pressure switch: 2-pole insulated return

- Switching capacity: 5 Watt Maximum

|

Pressure switch 6.00 PSI |

|

|

VDO Pressure switch 6.00 PSI - 1/8-27 NPTF

Part-number:

VDO 230-112-003-012C

- Pressure switchpoint: 6.00 PSI ± 2.00 PS

- Thread: 1/8 - 27 NPTF

- Contact close as pressure falls

- Pressure switch: 1-pole common ground

- Switching capacity: 5 Watt Maximum

|